Best Glue For Fishing Rod Tip

Edit ArticleHow to Fix a Broken Fishing Rod Three Methods:Fixing a Broken Rod BlankFixing a Broken Rod TipFixing a Broken Rod GuideCommunity Q&A Once made principally of cane or bamboo, most fishing rods today are made of fiberglass, graphite, or boron composite. Although the newer materials are more resilient, modern fishing rods still can break, but in most cases, a broken fishing rod can be repaired. The following steps describe how to fix a broken fishing rod and replace broken rod guides. Determine where the break occurred. Where the rod broke determines what you'll do next. If the rod broke near the tip, you'll either have to replace the tip top/tip ring or cut the broken tip and put a new, larger tip top on the rod. See "Fixing a Broken Rod Tip" for details. If the rod broke somewhere else, you'll have to cut out the break and insert a ferrule. Cut off the frayed ends of the break. Measure the diameter of each cut piece. Glue the male ferrule end to the end of the rod that includes the rod tip.

You can use an epoxy resin glue that sets as fast as 5 minutes, although some professional rod repairers prefer a 2-part epoxy that takes longer to cure to allow more time to position the ferrule correctly. Don't separate the male and female ferrule until finished with this procedure. Glue the female ferrule to the end of the rod that includes the rod handle. Allow the cement to dry thoroughly before continuing. If the break occurred near a rod guide or the reel seat, the rod's action will be largely unaffected.

Weight Loss Doctors In Northeast PhiladelphiaIf the break occurred elsewhere in the middle of the blank, the ferrule will dampen the action, particularly if it is a metal ferrule.

Designer Puppies For Sale Texas Cover the area where the ferrules meet the rod blank with epoxy.

Home For Sale Alliston Ontario

Lathe the splice to get it as close to the original diameter of the rod blank as you can. This requires using a lathe specially designed for fishing rods; if you don't have such a lathe, you can use fine sandpaper instead. Whichever method you use, work slowly. Do not bend the rod while doing this, as this will split the epoxy sleeve. Wrap the ends of the ferrules, and the epoxy sleeve, to match the wrapping around the rod guides. Once the wrappings are in place, coat them with a thin epoxy resin or polymer. If the rod broke near enough to a guide, you can move the guide over the splice before wrapping the ferrules. You can also further disguise the break by adding decorative wrappings elsewhere on the rod. Inspect the rod to see exactly what's been broken. Remove the old tip top. If you didn't have to cut the rod to remove the old tip top, you can remove it by applying heat to the glue holding it onto the rod tip and twisting gently to remove it. If the tip won't come off, you'll have to cut the rod at the end of the tip top as though the rod itself had broken there.

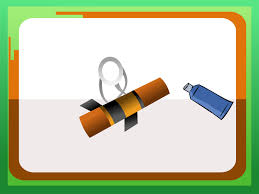

Avoid using too much heat, or you might damage the rod tip itself. Measure the tip of the rod for a new tip top. Glue the new tip top on. Apply the glue to the rod tip, then affix the new tip top, gently twisting it into place so that it lines up with the other rod guides. As the tip top guide is more prone to wear than the other guides, if you have to replace the tip top, you should get a replacement with a guide ring of either tungsten carbide or aluminum oxide, both of which are more resistant to grooving than steel. They are more susceptible to side impact damage (crushing), however. Measure the diameter of the broken guide. Heat the epoxy sealing the guide wrappings. Cut the wrappings on either side of the guide with a razor blade. Remove the old guide and the rest of the guide wrappings. Put the new guide in place. Wrap the feet of the new guide to secure it. If, after reading the above instructions, you find it too challenging to fix a broken rod yourself, you can take your rod to a professional repairer to have it fixed for you.

You can find one through your local sporting goods store or on the Internet. Instead of repairing your rod to close to its original length, you can take a rod that broke 1/3 to 1/2 the distance from the handle to the tip and convert the tip section into an ice fishing rod.for gluing reel seats, tip tops etc RodDancer Roddance Optimum Flow 5 minute Epoxy Glue This Optimum Flow Epoxy has a 5 minute drying time, great glue for Rod builders where you have smaller gaps, for tip tops etc This is equilivant to FlexCoats 5 minute glue. Fuji Hot melt Glue Fuji Hot melt Glue a small practical Stick of glue , ideal for gluing on tip top guides and making other repairs . Stick of Glue that can easily be melted, Ideal for fixing tip tops on to Rods. Can be remelted when set. Tip some rod builders use a small amount of this on the foot of guides to hold them in place while whipping the guide onto the Rod. RodDancer Ultimate Epoxy Optimum Flow - Slow Cure

Optimum Flow Epoxy - Slow Cure is a 2-component Epoxy liquid specifically designed for the demands of adhering fishing rod components. Designed for adhering parts which do not have optimum fit, or may require the filling of slight gaps, Optimum Flow Epoxy... RodDancer Ultmate Epoxy Optimum Flow 15 Roddancer Ultimate Epoxy Optimum Flow 15 , is a two part Epoxy Glue that is very liquid when mixed together, this alows it to be used where there is not much space, for the glue.Optimum Flow Epoxy - 15min is a 2-component Epoxy liquid specifically designed with gap-filling... RodDancer Ultimate Epoxy 5 minute RodDancer Ultimate Epoxy Gel-5min is the perfect Epoxy Gel adhesive for bonding any Fishing Rod Component that requires a quick, strong, gap-filling bond. Specifically designed for mounting tip-tops, where slight gaps may exist between the taper of the rod... RodDancer Ultimate Epoxy 15 Minute RodDancer Ultimate Epoxy Gel-15min is a 2-component Epoxy Gel specifically designed for the Rodbuilder who requires an extremely strong bond with a slightly longer working time than 5 min.