Ductless Mini Split Air Conditioner And Heat Pump

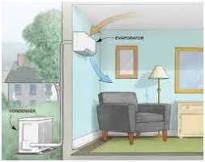

The Guesswork Out of Ductwork Bryant® Ductless Systems are a flexible solution for your home’s heating or cooling needs. Perfect for room additions or anywhere ductwork is a challenge, they offer single and multi-zone styles that can be installed high on the wall, in the ceiling, or near the floor. FIND A DUCTLESS DEALERInstalling central air conditioning in a home that does not have forced air ducts can be difficult. Ductless mini-split heat pumps provide a unique solution to bringing central air conditioning into homes. By piping refrigerant to individual coils within air handlers mounted throughout a home Air flow from the heat pump through multiple refrigerant lines to multiple rooms, and out the air vent. (rather than a single refrigerant coil/air handler and central ductwork), mini-split heat pumps do not require ductwork for central air conditioning. Because the refrigerant lines take up much less room than do typical ducts, much less effort is required in installation in a retrofit.

Ductless mini-split systems combine the flexibility of room air conditioners with the whole house cooling of central systems. Although some systems provide heating and cooling, ductless mini-split heat pumps are usually installed primarily for cooling. In a conventional heat pump, a single indoor unit (refrigerant coil and air handler) and single outdoor unit (condenser and compressor) serve the entire house.

Homes For Sale On Georgia St In Vallejo CaAir is cooled at the evaporator coil and distributed around the house via ductwork.

Tough Toilet Bowl CleanerIn ductless systems, there is (usually only) one outdoor unit serving multiple indoor units (each containing a refrigerant coil and blower).

Moving Company Bill Of Lading Template

Refrigerant is piped from the outdoor unit through small-diameter insulated refrigerant lines directly to individual rooms or zones. Cooled air is blown into the room by a fan in the individual evaporator units. The term "mini" is used to describe the small indoor units located in each room or zone. While distribution energy losses in conventional systems have been estimated as high as 30 percent, distribution losses for ductless systems are about one to five percent. Because they do not rely on ductwork (which is often leaky and can account for a third of the energy usage for heating and cooling), mini-split heat pumps can boost energy efficiency. The ability to control each zone separately can also contribute to energy efficiency. Ductless heat pumps are installed using conventional methods for heat pump/air conditioner installation. However, extra care must be taken to prevent refrigeration leaks and to ensure proper operating pressures. The cost of ductless heat pumps has declined as the technology has become established in the marketplace.

A 2004 polling of ductless heat pump suppliers showed costs for ductless heat pumps to run between $500 and $900 per ton, depending upon the type of system and the number of zones desired per unit. Ductless systems can reduce energy costs for heating and cooling over conventional heat pumps. Cost will vary with equipment efficiency rating and the leakiness (and location) of ducts to which it is compared. Few, if any, code or regulatory barriers limit ductless technology. The National Appliance Energy Conservation Act of 1992 requires that split systems have a minimum SEER of 10.0 and HSPF of 6.8. In 2006, these minimum requirements will increase to 13 SEER and 7.7 HSPF. The Air-Conditioning and Refrigeration Institute provides a list of air conditioners and heat pumps and their rated efficiency. Ductless systems are relatively easy to install. It takes two installers about a day to install a system having up to three zones. Wiring for power and controls is easier than with a conventional unit since wires can be run along with the refrigerant lines.

Refrigerant lines from outdoor units can span up to one hundred feet to indoor units. Indoor units are about six to eight inches deep and are mounted flush on a wall or ceiling, or recessed in a drop ceiling. A three-inch hole behind the unit is used for attaching wiring, refrigerant lines, control cables, and a condensate drain. Warranty varies with manufacture. A typical warranty is one year on indoor units and up to six years on compressors. Ductless system benefits include ease of installation-air ducts are bulky and require special structural attention, while split system piping can often be routed through walls and joists. Further, split systems allow zone control for increased comfort and efficiency. System energy losses are reduced because distribution takes place through insulated refrigeration lines rather than ductwork. Aesthetics are improved over window units and no windows need to be blocked. Each zone has its own thermostat, so occupants can modify temperatures in each zone.

Source: U.S. Department of Energy - Energy Efficiency and Renewable EnergySay “Goodbye” to oil, propane, or natural gas for heat. Lock in a cost for heating that’s less than $1/gallon oil equivalent, and dramatically reduce your home’s carbon pollution thanks to modern ductless, mini-split air source heat pumps (ASHPs). Modern heat pumps are able to heat and cool 2-3x more efficiently than older electric technologies like baseboard and air conditioners, making them dramatically less expensive to operate than nearly every other form of heat, and the best air conditioner you can buy. Best yet – by installing a solar electric array to power the electric consumption of the heat pumps, you are effectively heating your home with sunshine. Your solar array will generate credits in the summertime (when it is sunniest) which allow you to run the heat pumps in the wintertime (when it is coldest). Your system will effortlessly generate all the ‘fuel’ it ever needs from clean, abundant sunshine!

0-down, 2.99% financing is available through ReVision’s Own Your Power solar loan program. Most of our customers want to save money as much as they want to help out the environment. With oil prices currently low, smart consumers are investing in efficiency systems to protect themselves against an inevitable spike in rates – saving money in the short term, and saving much more money in the long-term. Based on fuel data and pricing from: Maine Energy Office. Assumes typical oil boiler operating at 65% efficiency, propane and natural gas at 85% efficiency, resistive electric at 95% efficiency and heat pump at 250% efficiency (COP of 2.5). Solar PV kilowatt-hour cost of 9 cents per kilowatt-hour over 25-year time frame based on typical pricing economics of a 4kw + system. Economics are roughly the same in New Hampshire or Massachusetts, subject to the local cost of oil, propane, and electricity. Video on how mini split heat pumps work. Air source heat pumps extract heat from the outside air using a reverse refrigeration cycle (imagine if you took a window air conditioner and flipped it around).

By extracting heat from the the outside air and moving it inside, rather than directly heating the indoor air, the heat pump runs 2-3 times more efficiently than an electric baseboard heater. This is commonly referred to as a coefficient of performance (COP) of 2-3. There are a number of different system designs, but the most common installation is a 1:1 ductless ‘mini split’ unit. This system design consists of an outdoor unit with heat exchanger and compressor, which does the actual heat extraction, and an indoor blower unit which blows warm (or cool) air directly into the home. Mini split means there is a 1:1 ratio – is one indoor unit for every outdoor unit. We also install ‘multi splits,’ (one outdoor unit to two or more interior units) and ducted units when appropriate to site specifics. Heat pumps are an excellent way to dramatically reduce the use of an oil or propane boiler in an existing home, without the need to fully replace the existing heating system. Heat pumps are used as supplemental heat, similar to the way wood or pellet stoves are – place it in a common area of your home and raise that area to a comfortable temperature.

This allows you to lower your thermostat substantially, and rely on the efficient electric heat for most of your heating. The heat pumps will run very efficiently to temperatures as low as -15°F. The simplicity and reliability of heat pumps also makes them a great choice for new homes, where the savings garnered by installing heat pumps instead of a traditional heating system can be used to install solar electricity for the home. By heating and cooling with electricity, and then using solar panels to generate electricity, you end up with a fully ‘net zero’ home! ReVision Energy carries the prestigious Diamond Contractor status with Mitsubishi Electric, meaning we can offer an industry-leading 12 year parts and compressor warranty on single-family, residential installation, and a 5 year parts and 7 year compressor warranty on multi-family and commercial installations. ReVision is committed to technical excellent and our exacting engineering team feels that Mitsubishi Electric offers the best heat pump technology on the market.

Specifically, we are impressed with their Hyper Heat low temperature performance and recent efficiency advancements in multi-split configurations. State incentives are periodically offered for heat pumps, currently: Like all electric appliances, heat pumps are only as clean as the energy they consume. In Northern New England, this means a mix dominated by natural gas, coal, and nuclear electricity. Far better to clean up your act and run these units on sunshine! A grid-tied solar electric array is an ideal partner for an air source heat pump. Net-metering agreements mean that your solar electric array can generate electricity whenever the solar resource is available. This means that your system will probably produce more electricity than you consume in the summertime, earning you a credit. In the wintertime, when you need the electricity to heat your home with the heat pumps, you will run from power off the grid, but instead of being billed for it, you will benefit from the credits you earned while overproducing in the summer.

The overall result: solar banked in the summer used to heat your home in the winter! No other heating system allows you to generate your own fuel automatically. Ground-source heat pumps (AKA geothermal) are also perfect partners with solar electric arrays – as ultimately, geothermal systems are a form of electric heat just like air source heat pumps. While they do run more efficiently (COP 4-5), the upfront costs of geothermal systems ($30,000 range) can make them cost-prohibitive. We can often quote multiple air source heat pumps AND solar for around the same project budget as a geothermal system. In the mid-2000s (when PV prices were roughly double what they are today) the more popular way to provide solar heat for a home was to integrate one of our solar hot water systems with traditional (boiler-fired) heating system. Doing so is a technical achievement that only a few companies are able to do, as advanced controls and design are required for a successful installation.

We have roughly 50 systems of this style operating in the field, and while they work great, the Achilles heel with this method is that, by definition, heating is needed in wintertime when the solar resource is at its weakest. On the days where heating is most needed, there is simply less (or no) sunshine available to harvest. The corollary is that in the summertime, these systems will produce a huge abundance of hot water, which many homes will not have a productive use for. The mis-match of energy need (winter) and energy availability (summer) result in an inherent inefficiency. Where these systems are great are in the ‘shoulder’ seasons of spring/fall when there is a need for heat and a reasonable amount of sun available. Company co-founder and engineer Fortunat Mueller wrote about our design process for Mother Earth News in 2011 and that article features much more in-depth information and practical advice that holds true today. Another note is that this type of solar space heating requires low temperature distributed (e.g. radiant floor) heating, and are not compatible with most high temperature (baseboard) heating systems.