Vacuum Cleaner Motor Datasheet

(1) 1-Stage Wet/Dry Vacuum Cleaner (8955) (1) 1 1/2" O.D. Hose Connections (1) 7' x 1 1/2" I.D. Vinyl Hose (3) Hold Down Clamps 10 gal., 1-1/8 bu. recovery capacity, 8.0 amp motor Positive water shut-off Can be used as a blower One-stage bypass motor for wet/dry operation 10 Gal and 1-1/8 Bu Sealed Suction in Water The variations of this product are shown below. Not all product variations may be available from your local Authorized Milwaukee Distributor or Online Retailer. Please contact the distributor or retailer for availability. 1-Stage Wet/Dry Vacuum Cleaner (1) 1-Stage Wet/Dry Vacuum Cleaner (8936-20) (1) 1 1/2" Conversion Unit (1) 7' x 1 1/2" Hose (1) Dolly Caster Assembly (1) 1-Stage Wet/Dry Vacuum Cleaner (8950) (1) 1-Stage Wet/Dry Vacuum Cleaner (8965) (1) Foam Filter Sleeve 12 Inch Cleaning Path---4.5 Gallon Capacity Dump Out BagDetailsSanitaire Upright Round Vacuum Cleaner Belt, designed to fit all Sanitaire Uprights where the belt…

Details9 Eureka Allergy Micro Lined Vacuum F&G Bag Sanitaire Kenmore 5062, Uprights, White Westinghouse… Lightweight (12 lb.) upright vacuum for easier maneuverability than heavier upright vacuums 18 dry qt. capacity Tietex fabric shake-out bag can be emptied and reused to save costs associated with disposable bags 5 amp motor delivers 120 cubic feet per minute (CFM) of air flow Handle has an automatic locking system with a foot pedal release for usability, and drops down flat for cleaning under furniture and for storage Earned a CRI Seal of Approval for soil removal and indoor air quality in the commercial use vacuum category 19.7 x 14.6 x 7.5 inches ; Shipping Weight: 14.4 pounds (View shipping rates and policies) Item model number: EUKSC679J #1,624 in Industrial & Scientific (See Top 100 in Industrial & Scientific) This was a lemon ... The brush roller was bad first time vac was used .. Ordered another one from Amazon and installed it, it lasted about ten uses and then the vac.

Great cheap commercial vacuum cleaner. Does what I need but the belt could last longer but I know to complete a supply of them on hand at all times. Very disappointed with this product. The first one we received broke down in a couple of weeks so I returned it to Amazon... This vacuum is light, yet very powerful. I added the magnet to grab paperclips and metal items. You will be very sat8with this commercial grade vacuum. Old fashioned things last longer and work harder.In my experience, the best appliances are simple and old-school. You could really roll the dice buying vacuums. Very good product and service also. I had to return after a while, was to heavy and small. Not worth the money. See and discover other items: 12 amp upright vacuumThe requested URL /cgi-bin/catalog/e_catalog.cgi?CAT_ID=rs_540sh was not found on this server.Proper ventilation of bypass vacuum motors in cleaners and other appliances is critical to attaining their design life. This is a critical design consideration in the application of Lamb bypass vacuum motors.

This discussion is not intended to be critical of any particular appliance. Rather, it puts forth considerations to be taken into account in the application of Lamb bypass vacuum motors in appliances. The most common problem encountered is recirculation of the cooling air where there is not a positive separation between the cooling air inlet and discharge areas.

Furniture Store In Lanham MdBy using heated air to cool the motor, it can run at elevated temperatures and thus can shorten the life expectancy of the unit.

Puppies For Adoption Iowa CityWhile the appliance may pass temperature tests at agencies with this condition, the elevated temperature caused by the recirculation can put the motor at risk of premature failure.

Lab Husky Mix Puppies Michigan

Care must be taken to prevent recirculation of cooling air. Many effective methods have been employed to prevent recirculation of ventilation air. These include using foam rings and other sealants between the vent fan housing and the appliance body, having the motor extend outside the unit housing, etc. It is important to ensure that only cool, ambient air is used for motor cooling. The discharge air should be directed away from the cooling air inlet to ensure that outside ambient air only is used for cooling. Another common problem is the result of restricted inlet or discharge area for the ventilation air. Lamb recommends that a minimum of 3 square inches of area be allowed for both the inlet and discharge of the cooling air. If this area is not provided, the motor temperature can be effected to the point that it will run hotter than normal and can result in premature failure. The appliance should be installed or used in an area where the ambient temperature in not elevated to high levels.

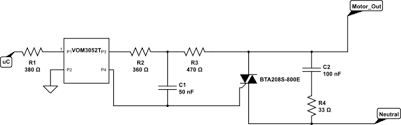

For a central vacuum cleaner, such areas as small closets, attics, garages can have very high ambient temperatures that will create problems for the motors in operation. Continued operation of the vacuum motor at very high temperatures can lead to premature failure. One of the most common problems seen is bar movement of the commutator. Commutator construction varies but most of the units that Lamb uses have the bars held in place with a moulding compound. These commutators are very durable and have been highly reliable when the operating temperatures of the motors are within agency limitations. I have build a circuit with the purpose of driving a ~1000VA AC motor. The motor controller fires a triac only at zero crossings. The circuit is as follows: Both C2 and C1 are ceramic capacitors. R4 is a 5W resistor, the rest is regular 1/8W. The BTA208S-800E has a proper heatsink mounted directly to it. The problem is this: after a few seconds of operation the circuit gets really hot and a little later starts to malfunction (random firing, loss of speed control).

The motor is from a old vacuum cleaner and therefore I have no datasheet for it (Google didn't yield any results either). The circuit is one found on the internet, since I do not have the required knowlegde to calculate RC snubbers. The BT208S is a smallish SMT triac- you will be dissipating 5-6W (assuming European mains) with a 1000VA motor. That's a lot of power.. Probably your heat sink is woefully inadequate for the power dissipation and the triac is overheating. If just mounted on FR4 board the Rth-ja is 75K/W so 5W would heat it to about 400C -- so maybe your heatsink is better than that, but nowhere good enough. Edit: For that amount of power, to keep the junction temperature sensible, you either need a BIG heatsink coupled thermally to the MT2 of the triac (might require an aluminum board) or a fairly large heatsink with a lot of air flowing over it. If you just want to turn the motor on and off, forget about the triac and use a power relay. R3 = 2.7k, R2 = 220R, C1 = 100n and connects to NEUTRAL, NOT gate.